Demand for SolidWorks Developers Continues to Expand

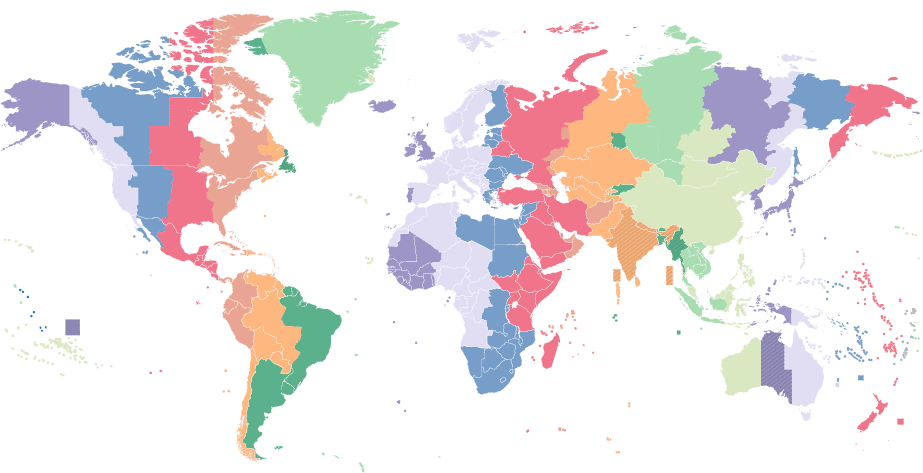

SolidWorks is the second most prominent computer-aided design (CAD) software, commanding an estimated 13.76% of the market share. With companies scaling product design and racing to complete prototypes, the platform has become deeply embedded in industries ranging from aerospace to consumer electronics, supporting over 3.2 million users worldwide. It’s therefore no surprise that demand for SolidWorks engineers is soaring.

As digital prototyping methods become the norm, finding a skilled CAD expert who can model effectively and integrate with simulation, product lifecycle management (PLM), and manufacturing workflows is more important than ever. However, many SolidWorks CAD resumes look similar on paper, and it is challenging to distinguish candidates who can quickly iterate on designs while delivering production-grade results.

This guide will provide insight into how best to evaluate SolidWorks programmers, whether you’re hiring for rapid prototyping, manufacturing design polish, or simulation-driven workflows. It covers the core technical skills any candidate should possess, how to evaluate different engineering levels, and which interview questions and answers can target real-world experience.

What Attributes Distinguish Quality SolidWorks Developers From Others?

SolidWorks engineers transform engineering concepts into production-ready models by designing, simulating, and documenting mechanical systems using the 3D CAD software. Candidates’ expertise goes beyond software knowledge—skilled engineers apply their deep understanding of 3D modeling principles to manufacturing problems with industry-specific requirements in mind. They accelerate product development timelines, minimize design iterations, and optimize team resources and costs.

Parametric Part and Assembly Modeling: As the core requirement, candidates should be skilled in advanced 3D part and assembly modeling with a strong understanding of clean, parametric designs. This skill is essential in fast-paced environments where adaptable models can help teams meet tight deadlines or deal with changing specifications. Engineers know how to build organized feature trees to ensure models are reusable as designs change. They are also familiar with advanced features like sweeps, lofts, shells, and multi-body operations. Finally, the best experts can manage mates, constraints, configurations, and subassemblies to ensure maintainable designs.

Design for Manufacturing (DFM) Awareness: The best SolidWorks candidates design with manufacturability in mind. They apply design for manufacturing (DFM) principles (e.g., minimum wall thicknesses, draft angles, and standard hole sizing) and account for real-world factors like material properties, machining tolerances, and production processes. In addition, candidates should be able to speak to their experience drafting detailed drawings, bills of materials (BOMs), and engineering documentation, as these materials are essential when taking a design to production. This foresight accelerates the transition from CAD design to physical product and reduces costs.

2D Drawings and GD&T Standards: Technical drawings are the source of truth for machinists, fabricators, and quality assurance teams, so candidates must be adept at creating dimensioned 2D drawings aligned with industry requirements. They should understand how to make section and detail views and annotate machine designs clearly (e.g., finishes and materials). In addition, engineers should have experience applying geometric dimensioning and tolerancing (GD&T) and be familiar with widely used industry standards like ASME Y14.5. Manufacturing variation can cause deviation from nominal dimensions, and GD&T defines allowable limits, ultimately affecting cost, quality, and production timelines.

Configuration and Design Table Mastery: Candidates should be adept at managing complexity with SolidWorks’ configuration tools. These tools empower candidates to build parametric models that adapt to changing requirements, produce multiple part variants or customizable assemblies, streamline pricing workflows, and prevent errors across product families. They are critical for industries where product families share a standard blueprint with customizations per client, such as automotive and consumer products. Candidates should be proficient in managing configurations from Excel-based design tables, automating part family generation, and minimizing duplication across CAD models. They should also understand how to apply these skills to control material, dimensional, and component-level variations from one main model.

Simulation Preparation and Geometry Optimization: Not all SolidWorks engineers run simulations themselves, but senior engineers understand how to prepare geometry for analysts. They may de-feature complex models, develop simplified representations (e.g., shells or beams), identify key boundary conditions or load paths, or guarantee proper mesh compatibility (e.g., by ensuring consistent wall thickness). Optimizing geometry proactively enhances collaboration, reduces turnaround times for simulation teams, and improves accuracy before prototyping.

How Can You Identify the Ideal SolidWorks Developer for You?

Start the hiring process with a clear problem statement, including defining your project scope, manufacturing needs, and workflow constraints. For example, consumer-facing products focused on aesthetics have substantially different needs than medical devices with strict tolerances. Consider whether you need long-term or temporary support. Hiring an engineer to take CAD ownership over the whole product lifecycle leads to additional requirements that may not be relevant if you are looking for a part-time contractor to assist with rapid prototyping. Each context demands its own level of expertise and complementary skill set.

Choosing a Junior, Mid-level, or Senior Engineer

The difference between a junior, mid-level, and senior professional can make or break a product; hiring the right kind of candidate ensures that role expectations align with outcomes. While early-career engineers are cost-effective and provide model support under guidance, technical leaders drive team-wide success with their strong domain knowledge and optimized product workflows.

Junior engineers with less than two years of experience typically create basic parts or support large assemblies under the close supervision of senior experts. They may complete simple tasks like reverse engineering standard components, organizing libraries, or modifying drawing formats. While they understand parametric modeling, dimensioning standards, and clean feature trees, they don’t always follow modeling best practices (e.g., they may create unintended references or incompatible file structures). Junior engineers are a good fit for established, supportive teams with transparent design review processes and CAD standards.

Mid-level engineers with two to five years of experience are prepared to be independent owners of entire components, subassemblies, or drawing packages. They are adept at managing revisions and changing requirements, with experience using configurations, design tables, and exploded views. Beyond design, they also take on broader or cross-functional team responsibilities like contributing to design processes (e.g., reviews), driving DFM considerations, and collaborating with specialists on simulations. Mid-level engineers thoughtfully consider the downstream implications of their CAD and will serve growing teams or product lines needing repeatable designs well.

Senior engineers with over five years of experience are technical visionaries who steer product architecture across the entire CAD lifecycle. They set team-wide standards to ensure consistency and manufacturability, including establishing modeling and drawing conventions, leading documentation efforts, and mentoring junior team members. Senior engineers possess all the CAD expertise and abilities of mid-level professionals; they also manage data workflows, effectively use PLM systems, and lead compliance efforts in regulated design environments (e.g., FDA or ISO). These experts are the only choice when dealing with manufacturability, sourcing challenges, or high-stakes design environments.

Complementary Technical Skills

Each product requires a unique skill set, and while your hire won’t need mastery of every CAD-adjacent skill, it is important to tailor requirements to project deliverables. A candidate’s selection of complementary CAD skills impacts production outcomes and team workflows.

Product Data Management (PDM) and PLM Systems: SolidWorks is commonly employed alongside tools like SolidWorks PDM or enterprise PLM systems (e.g., Teamcenter, Arena, or Windchill) to handle design revisions, access, and files. Specialists knowledgeable in PDM or PLM systems are invaluable for regulated or team-based environments; they secure CAD data, ensure alignment with project workflows, and prevent file duplication, broken references, and audit trail issues in regulated industries. Look for candidates experienced in checking models in or out correctly, managing version history, and troubleshooting broken references when restructuring.

Computer-aided Manufacturing (CAM) and Computer Numerical Control (CNC): A strong understanding of CAM workflows like SolidWorks CAM, Mastercam, and Fusion 360 makes models more machinist-friendly, especially when CAD directly interfaces with CNC or additive manufacturing equipment. Moreover, CAM and CNC knowledge minimizes redesigns, improves tooling compatibility, and enhances handoffs to fabrication. Engineers should understand how toolpaths are generated, which features create machining challenges, and when to avoid non-manufacturable geometries.

Rendering and Visualization: Though not always required, products like consumer electronics and packaging design projects commonly benefit from high-quality visualizations for stakeholder meetings or marketing purposes. Visualizations help simplify and communicate concepts to broad audiences and can be the deciding factor influencing stakeholder or consumer buy-in. Look for candidates who can produce photorealistic renderings of CAD models with accurate details (e.g., materials and lighting) using tools like SolidWorks Visualize, KeyShot, or Blender.

Sheet Metal and Weldment Design: Manufacturing methods in industries like automotive, HVAC, or structural steel impose strict design rules, making experience with sheet metal design or weldment tools within SolidWorks essential. Candidates should be capable of modeling with bend allowances, relief cuts, K-factors, and standard profiles; they should understand how to flatten parts, generate cut lists, and avoid over-constraining sheet geometry.

How to Write a SolidWorks Developer Job Description for Your Project

Start your job post with a clear description of your industry and product design challenges. Include the current stage of your project, whether focused on new product design, legacy part updates, or prototyping. Your technical requirements should detail your project’s tech stack and CAD environment (e.g., simulation or sheet metal tools) and specify whether you need someone to collaborate with CAM, manufacturing, or procurement teams. All job descriptions should include core skills (e.g., part or assembly modeling practices, GD&T) alongside industry-specific ones (e.g., design constraints like FDA regulations or ISO standards).

A range of job titles can apply to hiring a SolidWorks programmer. Beyond more specific titles like “Senior SolidWorks Designer,” broader titles like “Mechanical Design Engineer,” “CAD Drafter,” “Product Development Specialist,” or “Manufacturing Design Engineer” are often applicable to SolidWorks roles.

What Are the Most Important SolidWorks Developer Interview Questions?

Interviews are your first opportunity to assess a candidate’s real-world performance. Relevant interview questions facilitate a successful hiring and onboarding process, so tailoring them to your industry and project needs is important. However, you may start your interview with essential SolidWorks questions applicable to most engineering contexts.

Explain the difference between part, assembly, and drawing files.

This warm-up question evaluates a candidate’s ability to structure and manage files, a skill that is foundational for any SolidWorks role. While part files model single components, assembly files simulate real-world interactions between multiple parts with defined constraints. Finally, drawing files create 2D representations of parts or assemblies for manufacturing, with vital details like dimensions, tolerances, and annotations clearly depicted. Consider it a yellow flag if a candidate lacks this knowledge, as it is a sign that they may struggle with collaboration or version control.

What is your approach to creating assemblies with multiple moving parts?

Candidates must understand how to model movement accurately since complex assemblies are common in mechanical design. They should mention using mates to define part interactions and demonstrate awareness of assembly performance techniques for handling large datasets efficiently. Advanced engineers may also discuss exploded views for clear documentation, motion studies for validating design intent, and subassemblies for improved performance and modularity.

How do you ensure your designs are ready for manufacturing?

Design for manufacturing (DFM) awareness is a critical component of CAD engineering, ensuring the team can transform designs into manufacturable products. This skill is essential and protects prototypes from failure or excessive costs. Look for candidates who have collaborated with manufacturing teams and worked with design constraints around injection molding, machining, or sheet metal. They should also have experience incorporating GD&T standards.

Candidates who can simulate loads, stresses, thermal behavior, or other real-world conditions are prepared to validate models before prototyping and physical testing, saving time and resources. Though not all engineers will be simulation experts, understanding setup, meshing, and interpretation is practical for most agile prototyping environments. The best candidates will describe an example in detail, including the type of analysis (e.g., static, dynamic, thermal) and boundary conditions (e.g., force, torque, gravity, pressure) they used. They will clearly explain how they interpreted the results and review their design changes.

Why Do Companies Hire SolidWorks Developers?

Hiring a Solidworks programmer is a strategic investment in your product’s success. These experts use their CAD and 3D design mastery to drive projects from ideation to manufacturing. They bring essential mechanical innovation to the automotive, aerospace, consumer product, and industrial design industries.

SolidWorks engineers support various product lifecycle stages, such as assisting with early-stage concept models, fully constrained assemblies, or manufacturing-ready CAD drawings. They deliver precise models and fast prototyping cycles, avoiding design errors that can slow project timelines, inflate costs, or complicate vendor pricing. Their mastery of integrated simulation tools further improves efficiency, preventing the need for time-intensive and cost-intensive physical testing.

Understanding your role requirements—from core abilities like parametric modeling and assembly design to project-specific ones like simulation or PDM—will match you with a candidate who will bring business ideas to production. Whether you seek an engineer for rapid prototyping, production-grade development, or design automation, familiarity with the nuanced skill set of SolidWorks developers will help you hire top-tier CAD talent.