5 Key Tips for Smarter Sales and Operations Planning Implementation

S&OP can help a company create a long-term business plan to address supply chain disruptions. Make the most of this useful process with these updated best practices.

S&OP can help a company create a long-term business plan to address supply chain disruptions. Make the most of this useful process with these updated best practices.

Juan is a management consultant and expert in strategy, business planning, and process improvement who has helped implement S&OP at companies in multiple industries in Latin America. He has more than 20 years of experience as a senior and advisory manager for corporations including Mondelez International, Yanbal International, and PwC.

Previous Role

General Manager/FounderPREVIOUSLY AT

Since 2020, a slew of disruptions has obstructed the smooth operations of companies around the world, making it difficult for many to obtain the parts they need or get their products to customers. With significant economic uncertainty likely to continue in the foreseeable future, business leaders would be wise to prepare their companies to adapt more quickly and holistically to changing conditions.

Based on my extensive experience as a business planning and business operations consultant, I believe that the best way to do this is through sales and operations planning (S&OP). There are different ways to implement this collaborative methodology, but they all help companies develop a comprehensive long-term plan (12 to 18 months) that includes and aligns specific objectives for both the commercial divisions (product, sales, and customer service) and operations. I usually recommend also including finance (financial planning, budgeting, and cost management) and global strategy divisions when implementing S&OP, a method sometimes known as integrated business planning (IBP).

S&OP is an iterative process, so it regularly incorporates new input from stakeholders, enabling a company to respond rapidly to changing environments. And one of the chief benefits of my approach is that it can sync supply with client demand, while simultaneously matching daily operations to business objectives.

Companies that continually use new information to adapt can spot oncoming problems before they hit. For example, S&OP can alert firms that they may need to identify alternative manufacturers, vendors, or distributors to use when their regular partners can’t deliver products. A few years ago, I was working with an auto parts company in Ecuador that bought products to distribute to customers. We started having problems getting the parts from our vendors, which were based in China. But in the course of S&OP work, we had already researched backup vendors and found a parts distributor in Dubai. When obstacles appeared, we pivoted swiftly to get the products from this new source and minimized any impact on our customers.

Research suggests that our experience was not unique. According to assessments of more than 170 companies by McKinsey & Company, organizations with a well-functioning IBP implementation have “service levels that are five to 20 percentage points higher, freight costs and capital intensity (total assets divided by sales) that are 10% to 15% lower, and customer delivery penalties and missed sales that are 40% to 50% lower” than those of companies without effective IBP. Firms that have optimized IBP processes are 10% to 20% more productive than firms without them, and they respond to disruptive events quickly and effectively.

While S&OP is not a new process, the supply chain crisis has made it clear that too few companies are benefiting from it, either because they don’t have the right processes in place, or they aren’t using them to best effect. In this article, I share my insights about how to initiate or improve S&OP implementation so your company can weather supply chain problems and other potential disruptions, like freight or cargo container limitations, natural disasters, or IT outages.

Why S&OP Optimization Is So Important Now

I was introduced to S&OP more than two decades ago while setting up a manufacturing resource planning process for a cosmetics manufacturer. Back then, S&OP was a helpful way to maintain alignment on company goals and to increase productivity and reduce waste when specific problems arose that were exceptions to the norm. Today, in the aftermath of a generalized global supply chain crisis, S&OP has become a necessity for businesses that rely on multiple supply chain processes.

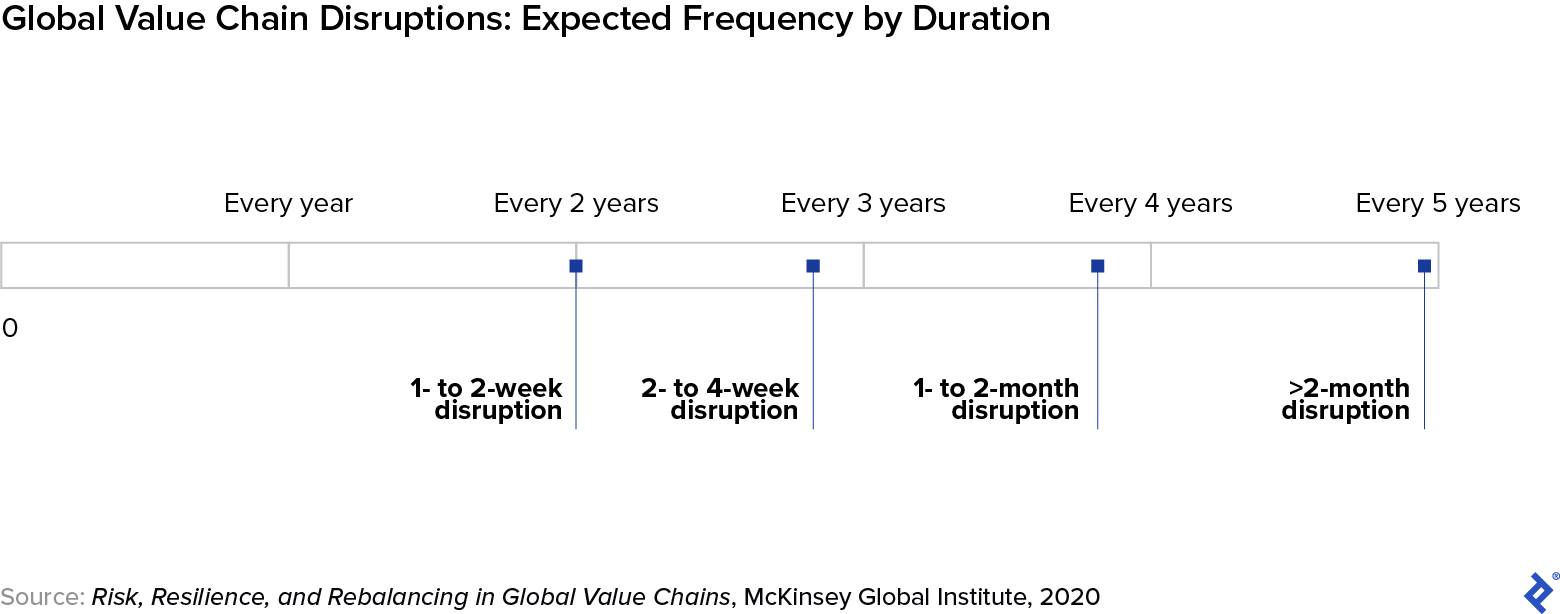

By now, the global supply chain disruptions caused by the COVID-19 pandemic, the Russia-Ukraine conflict, skyrocketing freight shipping prices, limited shipping container supply, and other factors have mostly subsided. However, there are always unknowns on the horizon. A McKinsey Global Institute report found that companies should “expect supply chain disruptions lasting a month or longer to occur every 3.7 years” and that the accumulated losses of these events could represent 42% of one year’s profit over a 10-year period.

Today’s long, complex supply chains are highly vulnerable to disruptions, including extreme weather events, terrorism, or trade disputes. That’s why S&OP is so vital. In fact, improving S&OP is the top priority for chief supply officers, according to a 2020 survey by The Hackett Group, and continues to be a key focal point for optimization. This concern is a tacit acknowledgement that simply putting a process in place isn’t enough. Poorly executed S&OP can also interfere with an organization’s ability to enlist alternate manufacturers, vendors, and distributors; identify alternative customers; or generally manage its market and demand.

Companies have always been concerned about unexpected events that could make it difficult for them to get the materials they need, produce enough to meet demand, or get their products to their customers. But for today’s hyperproductive businesses, typically relying on a highly fragile global value chain, the stakes are higher than ever before.

How the S&OP Process Works

First, let’s examine how S&OP is designed to function. It’s a highly collaborative process that involves input from every department at every stage. Initial implementation starts with the formation of a cross-functional S&OP team that works to coordinate and finalize plans at each stage. While your team’s exact composition will vary based on your company’s size and makeup, with the IBP approach, it usually includes people from the following departments:

- Commercial: product, sales, and customer service managers, demand manager, and demand planners

- Operations: production master scheduler, supply chain planners, buyers, quality assurance specialists, and distribution managers

- Finance: controller, costing accountant, and financial planning manager or budgeting manager

No matter who is on your S&OP team, the main steps in the process should be the same.

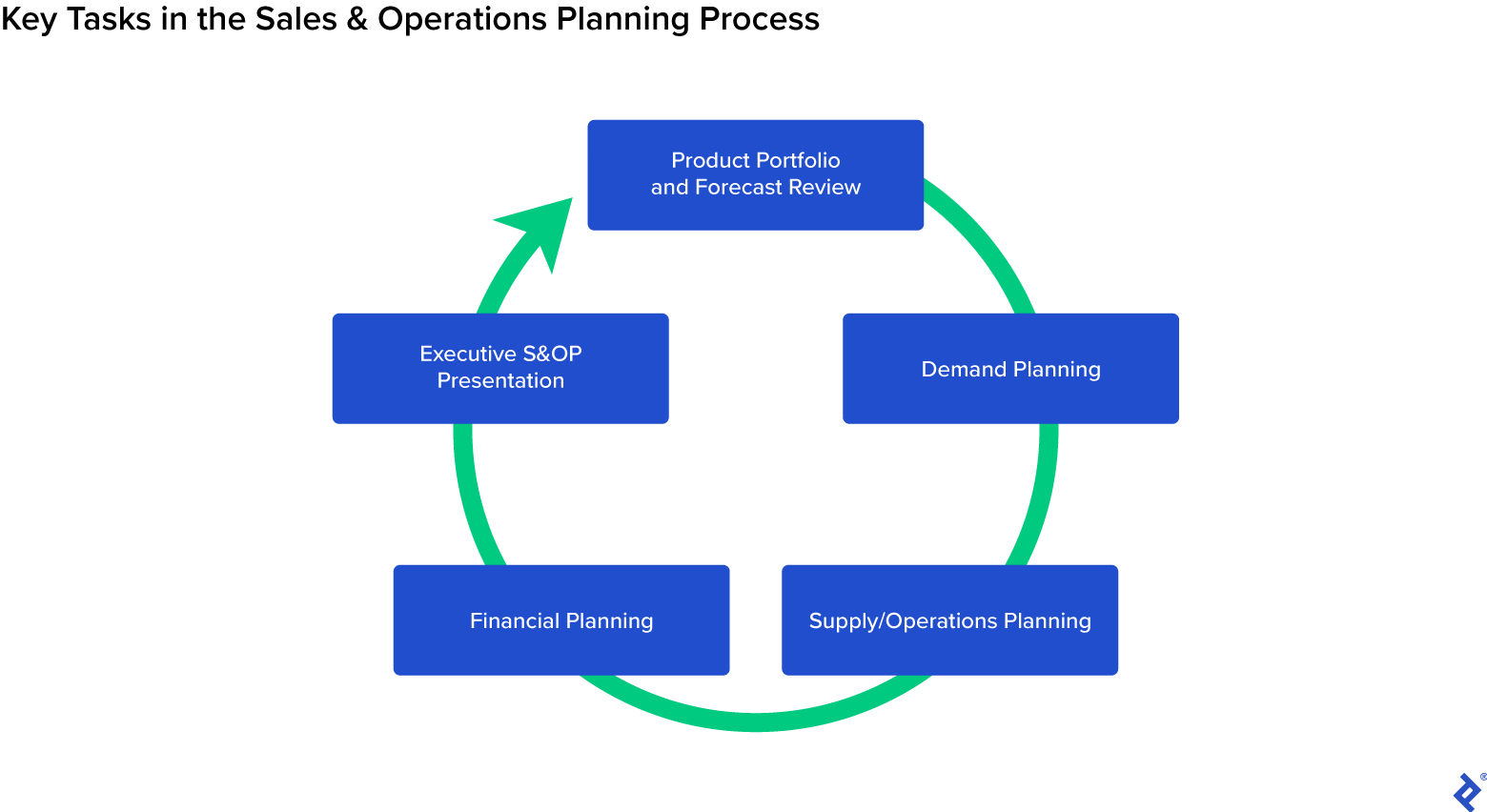

Core Steps in the S&OP Process

For proper S&OP implementation, you’ll need to accomplish—and repeat—all of these steps, but you can adapt them for your firm. For example, if one of these meetings becomes too long or complicated, you can divide it into two more-manageable ones. On the other hand, if a few meetings seem brief, you can combine them into one session.

- Product portfolio and forecast review: This step aims to deliver a unified corporate product strategy by analyzing the life cycle of each item in the company product portfolio. In order for the S&OP team to see an integrated review of each product or service that will go to market and be offered to customers, all departments involved in the S&OP process contribute data, like previous sales history and sales forecasts, inventory, production capacity, projected demand, and external events that could affect demand. The step also takes into account the most recent financial data, such as production costs, price, margins, holding costs, transportation costs, and so on. Since S&OP is an iterative process, after the first time through, the plan obtained in the last S&OP executive presentation is also integrated into this product review.

- Demand planning: The goal of this step is to ensure your company’s resources and sales goals are aligned, so that your production and supply chain can produce the inventory to meet anticipated customer demand promptly. This process uses past demand patterns and forecasts to predict need for products and services throughout the supply chain. Historical sales data, market trends, and other relevant information from the different departments are analyzed to estimate how much of a product or service will be required. Input and feedback from the operations group are especially important here so that you can define realistic demand levels according to product availability. The resulting demand plan is also analyzed and adjusted by the S&OP team to keep it aligned with strategic company goals like product line growth, discount percentage, and gross margins.

- Supply/operations planning: Next, the demand plan is translated into a supply plan, so that inventory and supplies are available to support the projected demand. Some of the tasks here include forecasting demand for raw materials, components, and other inputs; identifying and assessing potential suppliers; monitoring supplier performance; identifying and assessing potential risks to the supply chain (like freight limitations, supplier disruptions, or changes in market conditions), and developing plans to mitigate these risks; and making sure that the supply plan aligns with company priorities, such as inventory levels, resource utilization, fill rates, and percentage of perfect orders.

- Financial planning: Based on the demand and supply/operations plans, the financial team’s plan looks at the expected demand for a product or service and the related costs to estimate the company’s financial performance over a specific period. The main deliverables here are the projected P&L statement, the projected cash flow statement, and the budget compliance report. Cost is analyzed as a secondary concern. The cross-functional S&OP team reviews and discusses the plan alongside the demand and supply plans to see that the company’s financial goals are aligned with its operational goals and that the company has the resources it needs to meet demand and achieve its financial goals.

- Executive S&OP presentation: Next, the S&OP team presents the main points of the overarching plan to senior management to get executive input, approval, and buy-in. Typically, the team and leadership also consider “what if” scenarios to make decisions and final plan adjustments. Then the S&OP team incorporates recommendations from senior management and reviews the results before proceeding. The main deliverable of this meeting is a comprehensive, integrated plan that aligns with the company’s strategic, operational, and financial objectives. This plan will also inform the first step of the next period’s S&OP.

This S&OP cycle is usually repeated monthly, allowing stakeholders to stay aligned while continually refining the long-term plan based on changes to business needs, the supply chain, or market conditions. And since the day-to-day activities of every department connect directly to the long-term plan, each one can act swiftly to address unforeseen situations. Any changes in needs or circumstances, including new or altered constraints, should be communicated immediately to the entire S&OP team. Having a long-term plan that’s revised often also helps your company reach agreements with strategic vendors and customers, increase business responsiveness, and protect margins.

5 Tips for S&OP Success

Throughout my 25 years in the field, I’ve seen five implementation issues consistently impede successful S&OP. These are the best practices your business should follow in order to reap the full benefits of S&OP:

Collaborate Continually

Many companies see the S&OP process as linear: The commercial team presents a demand requirement, and the operations team generates enough inventory to support it. This approach won’t improve business responsiveness. Instead, you must get all participants on the multidisciplinary S&OP team to work together—not sequentially—from the start. The commercial group needs to communicate with operations while developing its demand plan so operations can start producing inventory. Likewise, operations has to talk to the finance group to determine how much inventory the company can afford to produce.

This kind of interlacing collaboration isn’t a given. When I started working with the local office of a large food manufacturing and processing corporation in 2005, the company didn’t have a dedicated S&OP team or an effective process. Although the commercial department presented a monthly demand plan, operations always altered it before developing its own plan—without sharing it with commercial. So there were two different plans running in parallel.

When I optimized S&OP at this company, the team I formed started doing objective historical data analysis and used the insights we gathered to correct the initial plan. The result? A unified, efficient plan that increased productivity, cut spending, and minimized losses. At last, operations was paying for the level of manufacturing that fit the commercial team’s promotional strategies—and the finance group had the cash flow to support them. Once they saw these benefits, the departments were more willing to collaborate with one another, making subsequent planning faster and easier.

Bring Leadership on Board

Having a CEO or general manager who’s not fully committed to the plan set by the S&OP team significantly weakens the process’s effectiveness. S&OP strives to bring and keep all departments in alignment. If a CEO isn’t aware of the process or doesn’t fully understand it and sets a different direction, subordinates will have to follow. At best, the company’s effort will be fragmented; at worst, the departments will be working at cross purposes. Yet, executives’ decision-making is often not aligned with S&OP because they consider it an optional addition, not as a system fully integrated into their day-to-day meetings and operations.

When I implemented S&OP in a large cosmetics corporation in Latin America, my first move was to sit with the general manager of one of the business units to discuss the steps involved. The manager already had a monthly committee meeting with his senior staff, so he didn’t like the idea of an “extra” appointment. I suggested merging the meetings and reviewing the main business KPIs and issues along with the S&OP plan. Our first session lasted more than 10 hours. But it showed the GM the methodology’s benefits, and he approved its use for the company. He helped define the plan, agreed to manage it, and gave the team unconditional support. Over time, the executive S&OP meeting was shortened to less than three hours.

Insist on Accountability

At every company, an S&OP process requires both the daily execution of tasks with due dates and a transparent chain of responsibilities. Every participant must be accountable for the duties they accept. Accountability should be a given, but I’ve seen many companies neglect it. And the worst situation an S&OP team can face is realizing the plan failed because somebody didn’t complete a task.

Rather than permit failures, senior management must hold all S&OP team members accountable. For that to work, responsibilities must be clearly defined. Individual assignments must be specified and tracked, and there should be repercussions for not fulfilling duties—as well as incentives for succeeding. One way to accomplish this is to tie earnings to performance.

Turn Off the Noise

For S&OP to function well, focus is key. In many implementations I’ve worked on, team members waste too much time reviewing historical results, often because they’re arguing and trying to justify their decisions or assigning blame for past failures. Historical results should only be points of reference for continuous improvement of the S&OP process. My general rule: Your team ought to invest one-third of its time looking at the past and two-thirds defining and analyzing its plan for the future.

Another kind of noise is poor data quality or management. Examples of this include data that’s inconsistent across departments, as well as lack of clarity about data definitions and preparation. At its first meeting, your S&OP team should define, agree upon, and implement a formal methodology for obtaining, unifying, and presenting information. This way, you can quickly make decisions based on data all departments trust, helping the company pivot even in the face of an industry-changing disruption.

Keep Information Flowing

Companies can only react as quickly as their communication channels and practices allow. Based on my observations, businesses that responded effectively to COVID-19-related supply chain limitations gathered and moved information swiftly throughout their organizations as they made collaborative decisions. Commercial, operational, and financial departments also need solid communication processes to stay in alignment as they respond to crises. This means having meetings at least once a week and sharing updates and information daily.

I saw the effects of inadequate communication at the food company I mentioned earlier. The commercial and operational departments didn’t share information consistently and didn’t follow a unified plan. Operations didn’t know the commercial team’s sales volume, so it generated too much product. Consequently, the company had unbalanced inventory levels and large volumes of product scrap due to expiration, meaning losses of close to $1 million. To tackle this issue, I developed an Excel spreadsheet that performed first-expired, first-out inventory management with a given forecast and inventory. This generated warnings that prompted operations to suggest adjustments to the estimates, letting the commercial team create promotions for at-risk products. Weekly meetings between teams strengthened this process, and the S&OP team reduced product write-offs by 80% in one year.

Information like inventory levels of at-risk products can’t wait. To increase responsiveness, companies should implement not only the monthly S&OP cycle communication but also good communication practices for day-to-day functioning, which some organizations call sales and operations execution (S&OE).

Optimized S&OP implementation helps your company anticipate and address problems quickly and efficiently. The long-term planning involved improves your ability to mitigate disruptions to your supply chains or other networks, while the emphasis on regular review and revision keeps business as usual a priority. And while the initial setup may require time, thought, and effort, this process will allow your company to respond adroitly to whatever comes at it. You can’t stop change—but you can be ready to meet it.

Understanding the basics

What are the components of sales and operations planning?

Since S&OP is customized to the specific needs of each company, precise steps and their order will vary. But the five core tasks that are consistent across organizations are product portfolio and forecast review, demand planning, supply/operations planning, financial planning, and the executive S&OP presentation.

What are the benefits of S&OP?

S&OP enables firms to respond more quickly and effectively to value chain disruptions, thus mitigating losses. It helps companies see problems in advance and identify solutions, like finding alternate vendors. S&OP also makes operations, sales, and finance functions more efficient by ensuring alignment on a unified plan.

Who is responsible for the S&OP process?

Everyone on the S&OP team, including personnel from the sales, operations, and finance groups, is accountable for their part of the process, and all the groups contribute data and insights. Senior management takes overall ownership, helping to define the process and then managing it while supporting all stakeholders.

Marysville, WA, United States

Member since June 8, 2022

About the author

Juan is a management consultant and expert in strategy, business planning, and process improvement who has helped implement S&OP at companies in multiple industries in Latin America. He has more than 20 years of experience as a senior and advisory manager for corporations including Mondelez International, Yanbal International, and PwC.

Previous Role

General Manager/FounderPREVIOUSLY AT