Kanban History: From 1950s Factory Floor to Today’s Remote Teams

From auto manufacturing in the 1950s to the modern digital workplace, Kanban’s evolution holds valuable lessons for today’s distributed project teams.

From auto manufacturing in the 1950s to the modern digital workplace, Kanban’s evolution holds valuable lessons for today’s distributed project teams.

Olamide is a project manager who specializes in leveraging technology to solve enterprise challenges. He is a former senior Agile project manager and senior IT business analyst for KPMG, and has also worked for Pluralsight and Alteryx.

Previous Role

Senior Agile Project ManagerPREVIOUSLY AT

Work is constantly changing. Projects multiply across the business and become programs. Programs get grouped into portfolios, and management practices become increasingly complex as organizations grow and begin to operate at scale. Even something as simple as an office presence is no longer a given.

Project managers are routinely tasked with handling uncertainty, to the point that adaptability is a core competency for the profession. Throughout all of this complexity, Kanban has remained a keystone of the management world for more than 60 years, enabling project professionals to maintain a clear, high-level view of processes.

It’s easy to see why Kanban has become an essential project management tool. As a lightweight and adaptable workflow method, it offers fit-for-purpose solutions that I’ve applied on projects across diverse industries, ranging from finance to energy to consumer markets. Kanban is capable of handling workflows on its own, but is particularly suited to being hybridized with other frameworks, scaling to an enterprise level, or even serving as the bridge to take organizations from Waterfall to Agile processes.

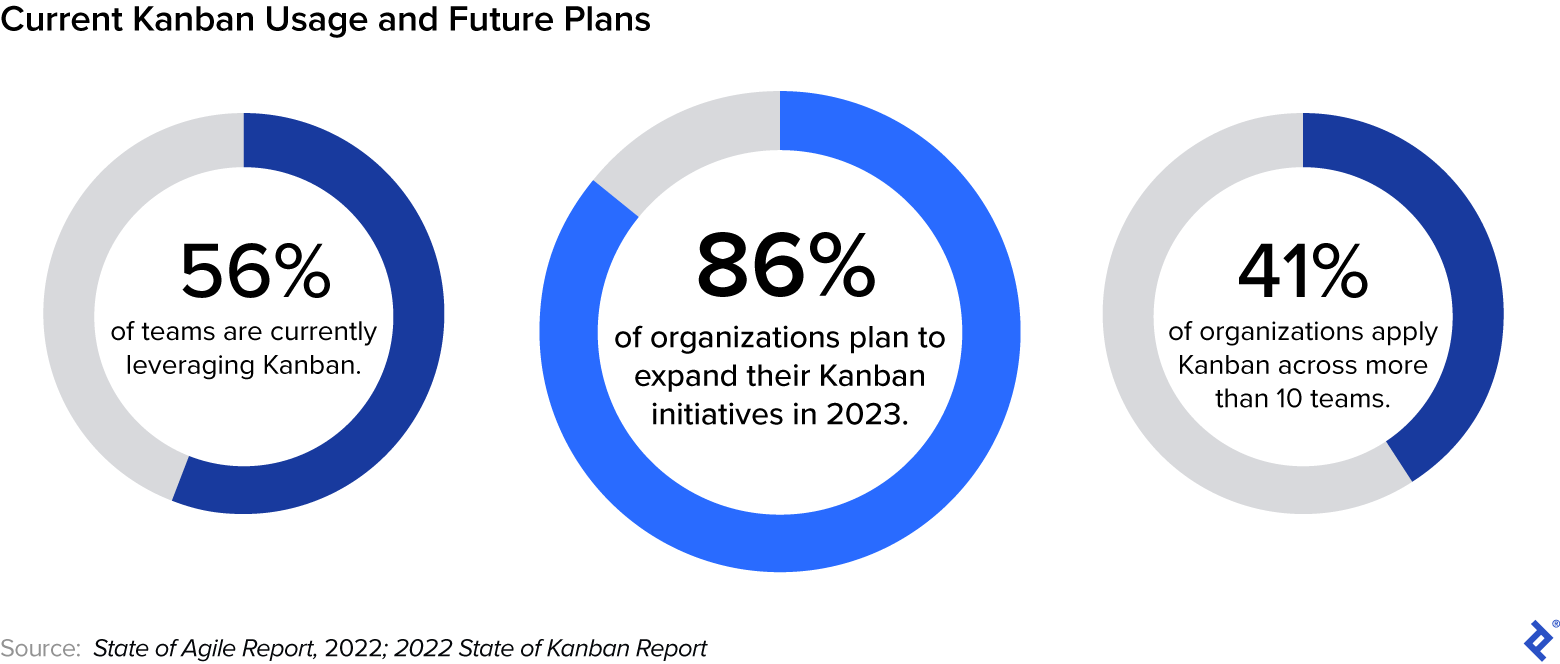

The 2022 State of Agile Report shows an explosive growth in the use of Kanban—up from 7% of respondents in 2020 to 56% in 2022. Considering the global shift to remote work that happened in 2020, part of that increase is no doubt due to Kanban use by remote teams.

That said, even with many businesses going hybrid or returning to the office, Kanban is still increasing in popularity. According to the most recent State of Kanban Report, 41% of organizations are applying Kanban across more than 10 teams, with 86% of respondents planning to expand their Kanban initiatives in 2023. Understanding the history of the Kanban system will help you gain a deeper understanding of why it’s so popular, and how to best leverage it for your projects.

Kanban System History: The Beginning

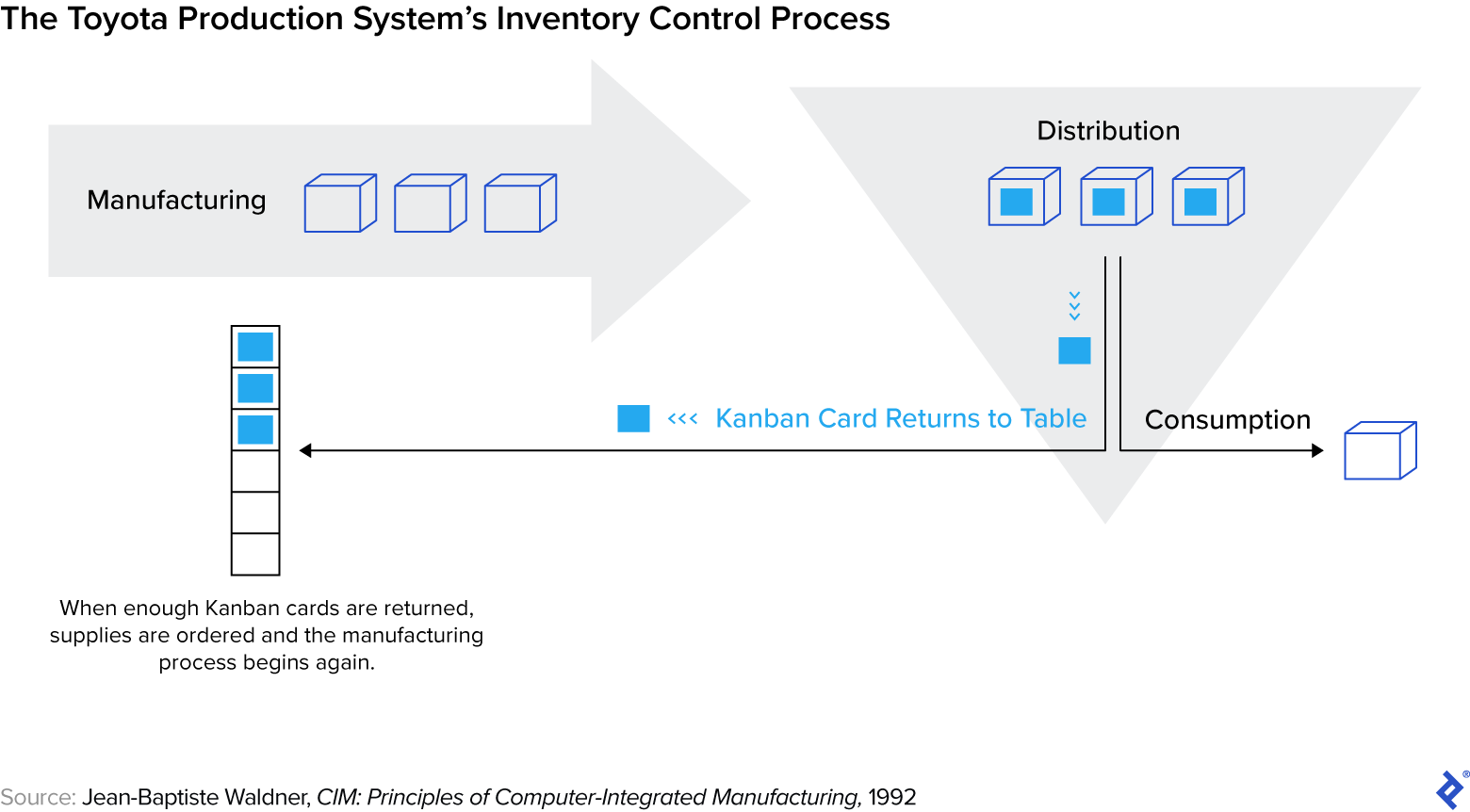

Kanban history has its origins in the Toyota Production System (TPS) invented by Taiichi Ohno. A director who had come up through the machine shop, Ohno sought to eliminate waste on the production line. Two of the areas he identified were overproduction and inventory: It was wasteful to make too many cars, but also wasteful to have unused raw materials sitting on the factory floor. His solution drew inspiration from supermarket operations, where food is stocked according to demand.

Applying this principle to factory production proved relatively simple: For each new car, a card containing instructions and supply information would be attached to the product during assembly, and move with it throughout the production process. Once the car was sold, the card would be returned to the start of the chain. When a predetermined number of cards were waiting to be reassigned to a product, this would signal the need for new cars to enter production, triggering an order of materials from the warehouse. The cards, named kanbans after the Japanese word for signboard, provided a visual aid to track a task from start to finish. By 1963, Kanban was in use at all Toyota plants. The manufacturing industry at large would take notice of the method and decades later, these principles would be applied to software development.

Kanban Board History: From the Factory Floor to the Whiteboard

In 2010, Microsoft engineer David J. Anderson published Kanban: Successful Evolutionary Change for Your Technology Business, which built on the work of Ohno and others to apply the principles of Kanban to software development. Central to this framework was the use of the Kanban board: This visual representation of a task’s journey through the production process reenvisioned the manufacturing model for software development. Instead of attaching the card to a physical object, the card is moved between one of several columns representing the task’s progress.

Anderson also laid out (and later expanded) core practices for Kanban:

- Visualize the flow of work. This is where the Kanban board is used in practice; it works from the premise that a visible workflow is more manageable and more easily tracked among users.

- Limit work in progress (WIP). By limiting the number of tasks a team or individual can handle at once, Kanban seeks to balance workloads and prevent burnout.

- Manage flow. Kanban enables tasks to move through each stage in the workflow with speed and efficiency.

- Make policies explicit. Kanban empowers teams with transparency; it helps individuals and teams understand how, why, and when work is done.

- Implement feedback loops. A Kanban team makes regular process and policy adjustments based on the results of review sessions.

- Improve collaboratively, evolve experimentally. The combined effects of increased transparency from a visualized workflow and the regular self-assessment of feedback loops create an environment in which teams work together to improve performance.

These practices form the basis for adaptive capability; together, they create a system in which anyone on the team can see and understand the workflow, assess what’s working and what isn’t, and adjust priorities accordingly.

Kanban Remote Teams in the Age of Digital Transformation

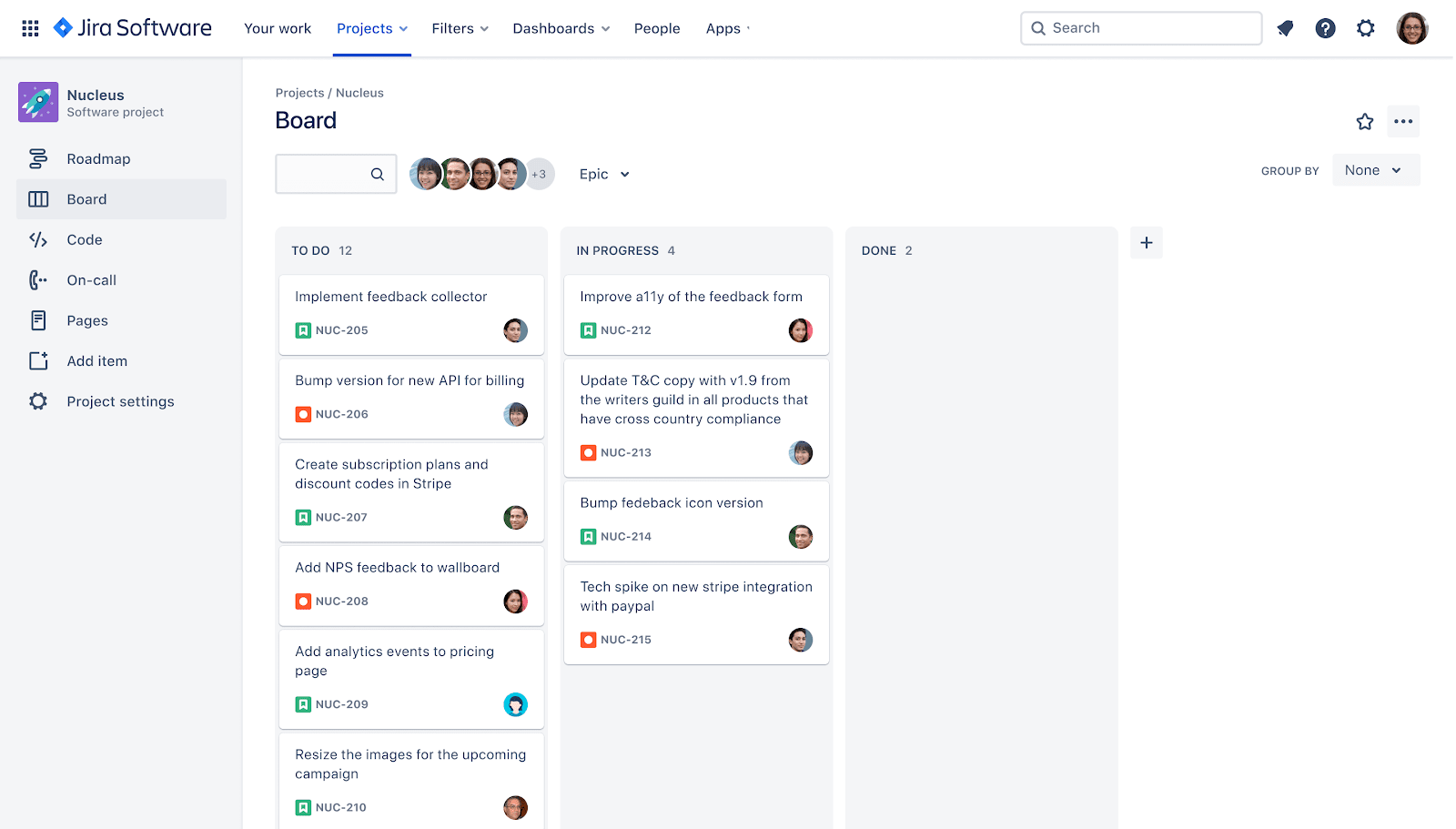

In the era of remote work, Kanban has evolved again from physical cards to project management software, such as Kanbanize, Jira, SwiftKanban, Azure DevOps, and Trello. A digital board provides distributed teams with a collaborative space in which to manage tasks, track activity, and maintain priorities from any geographical location. And WIP limits allow teams to manage their time and tasks more efficiently, placing the human touch at the center of productivity.

Jidoka, or “automation with human intelligence,” was a core concept of TPS and Lean manufacturing; it refers to effectively stopping work when a problem first emerges, so that processes can immediately be improved. While automation is valued, human intervention and innovation remain key. Thus, Kanban’s emphasis on feedback and improvement is especially valuable in companies that are new to remote culture and still working to solidify effective remote work or hybrid policies.

Kanban has also been adapted beyond project work to assist in achieving organizational agility as remote teams and companies begin to scale. Recognizing the role Kanban could play in enterprisewide operations, Anderson and co-author Teodora Bozheva released the Kanban Maturity Model in 2018. The model is designed to enable companies to gauge organizational health as they scale and is part adoption roadmap, part best practices guidelines. It lays out seven maturity levels to assess an organization’s ability to meet challenges such as customer satisfaction, workforce cohesion, and resilience in the face of unexpected market conditions. Other scaled Agile frameworks and toolkits, such as SAFe and Disciplined Agile, already have methods of their own for integrating Kanban at an enterprise level.

The Future of Kanban

While Kanban’s pre-software and pre-Agile era origins are seemingly far removed from today’s increasingly remote project environments, its principles of visualizing workflows, limiting work in progress, and continually improving processes are quickly evolving to incorporate AI-powered analytics and machine learning algorithms to drive project success.

Artificial intelligence promises to enable project management software to produce high-quality reports and insights, increase the accuracy of effort estimation, and automate routine project management tasks. Multiple Kanban platforms such as Atlassian and Trello have already begun to advance the framework using AI, proving once again its adaptability as new productivity tools and technologies are introduced.

Given how Kanban has progressed through new industries and ways of working over the course of 60 years, it shouldn’t be surprising that Anderson compares the changes it promotes to evolution. Its foundational principle, “Start with what you do now,” empowers project managers using Kanban methods to enact change, ensuring that the success of projects and companies is based on their fitness within their environment.

As we face increasingly volatile times, project managers can continue to depend on Kanban’s workflow method, which activates responsiveness to change when necessary, meets problems where they are, and adapts across industries and decades in an evolutionary arc that keeps pace with advancing technologies and ways of working. If you haven’t adopted Kanban’s principles, methods, and practices into your project work, now is the time to start.

Further Reading on the Toptal Blog:

Understanding the basics

What is the purpose of a Kanban system?

Kanban is a Lean framework that allows teams to visualize their workflow, making communication and process improvements easier to manage.

What are the benefits of a Kanban system?

Kanban’s flexibility and visualized workflows allow you to make process improvements without disrupting existing systems.

Does Kanban increase productivity?

Yes. Kanban’s key practices emphasize workflow management and collaborative improvement. A team using Kanban pays attention to how smoothly tasks move through the production process, and reassesses policies that aren’t working to improve efficiency.

What are the principles of Kanban?

Kanban has three basic principles: Start with what you do now; agree to pursue incremental, evolutionary change; and encourage acts of leadership at all levels in your organization.

When was Kanban invented?

Kanban was invented in the late 1940s—and refined throughout the 1950s and early 1960s—by a Toyota engineer.

Who invented Kanban?

Toyota engineer Taiichi Ohno created Kanban as a way to improve manufacturing efficiency.

Paris, France

Member since October 7, 2021

About the author

Olamide is a project manager who specializes in leveraging technology to solve enterprise challenges. He is a former senior Agile project manager and senior IT business analyst for KPMG, and has also worked for Pluralsight and Alteryx.

Previous Role

Senior Agile Project ManagerPREVIOUSLY AT